Calibration

Ultimately all measurements are used to help make decisions, and poor quality measurements result in poor quality decisions. Calibration ensures readings from an instrument are consistent with other measurements, confirms the accuracy of the instrument readings and establishes the reliability of the instrument. Calibration is a core competency of Sercal Calibration and Service.

Sercal has many years of experience in the field of calibration and their laboratory has been accredited by UKAS since 1991. Sercal provide a comprehensive calibration service for all types of testing machines, from all manufacturers, UKAS calibration certificates issued by Sercal are proof of measurement traceability to national and international standards as required by ISO/IEC17025:2015.

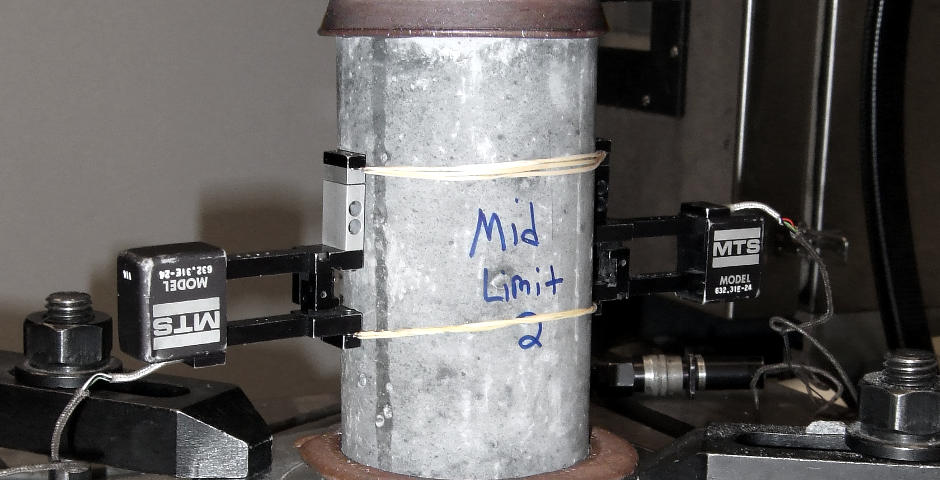

Compression testing of concrete allows today's civil engineers to specifiy and use the perfect mix composition and curing regime to produce the many different elements required in modern buildings.

Find out more about Calibration of compression testing machines for concrete

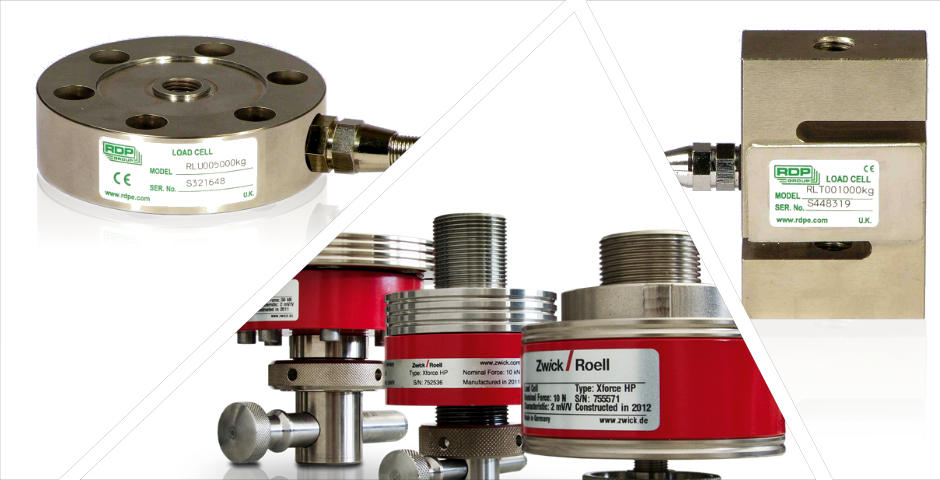

All load cells are subject to deterioration due to use, mistreatment or ageing. Regular calibration will establish the current performance of your load cells. Whether used in instrumentation and testing, weighing or overload systems, Sercal can provide calibration to satisfy your quality or safety regime.

Worldwide, steel producers yearly make millions of impact tests to see whether their steels meet the specific strength requirements for applications such as ship building or pipeline construction.

Read more: Sercal inspection and calibration of Charpy machines

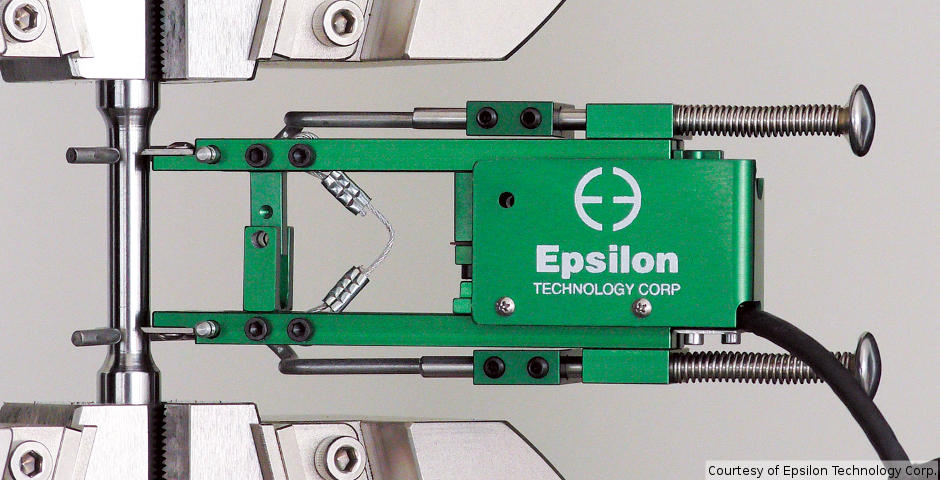

There is a large range of extensometers available on the market today, from clip-on and sensor arm contact units through to Video, Inductive and laser non-contact units. One thing they all have in common though, is the need to be calibrated to recognised standards at regular intervals. Sercal can provide calibration of all types of extensometers to BS EN ISO 9513:2012 and ASTM:E83-10.

The first creep testing machines were created in 1948 to test materials for aircraft to see how they would stand in high altitudes. Nowadays they are used widely in industry to test and compare materials and components while under long-term stress including tension, compression and flexure.